Boiler

Options for 2 Pass dryback, 3 Pass dryback, or 3 Pass wetback design. Pressures from 15 – 300 psi steam. Roller fireside access on dryback models-bearing supported single-hinged rear door for total fireside access on dryback models. Handholes for waterside access.

Economizer

A feed water economizer reduces steam boiler fuel requirements by transferring heat from the flue gas to incoming feed water. Boiler flue gases are often rejected to the stack at temperatures more than 150°C to 300°C higher than the temperature of the generated steam. Generally, boiler efficiency can be increased by 1% for every 40°C reduction in flue gas temperature. By Recovering waste heat often reduce fuel requirements by 5% to 10% and pay itself in less than 1 year.

Blowdown system

With manual control of surface blow down, there is no way to determine the concentration of dissolved solids in the boiler water nor the optimal blow rate. Operators do not know when to blow down the boiler or for how long. Likewise, using a fixed rate of blow down does not take into account changes in make up and feed water conditions, or variations in steam demand or condensate return. An automatic blow down system optimizes surface blow down rates by regulating the volume water discharged from the boiler in relation to the concentration of the dissolved solids present.

Steam condenser recovery system

It’s vital for steam users to make the best possible use of the energy and hot water in steam, so effective condensate recovery is essential. Condensate is the hot, treated water produced as steam releases its heat energy. It’s a valuable resource that contains around 25% of the useful energy in the original steam. It makes sense to return it to the boiler, instead of dumping it to drain. In most applications a goal of 75-80% condensate return is reasonable.

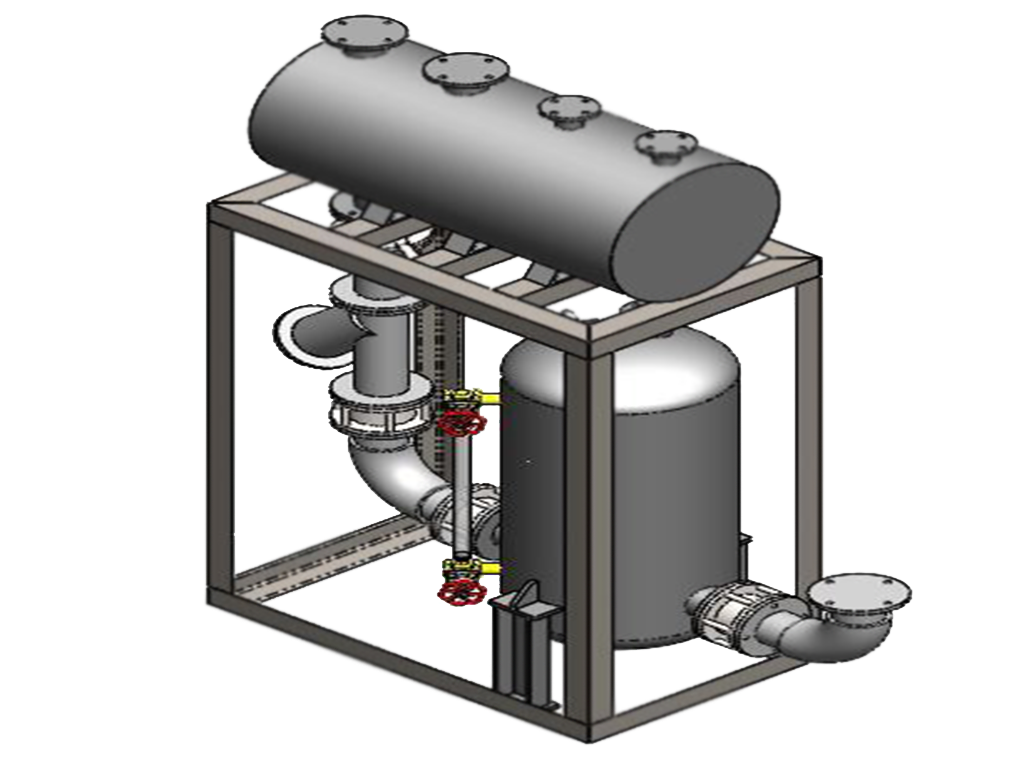

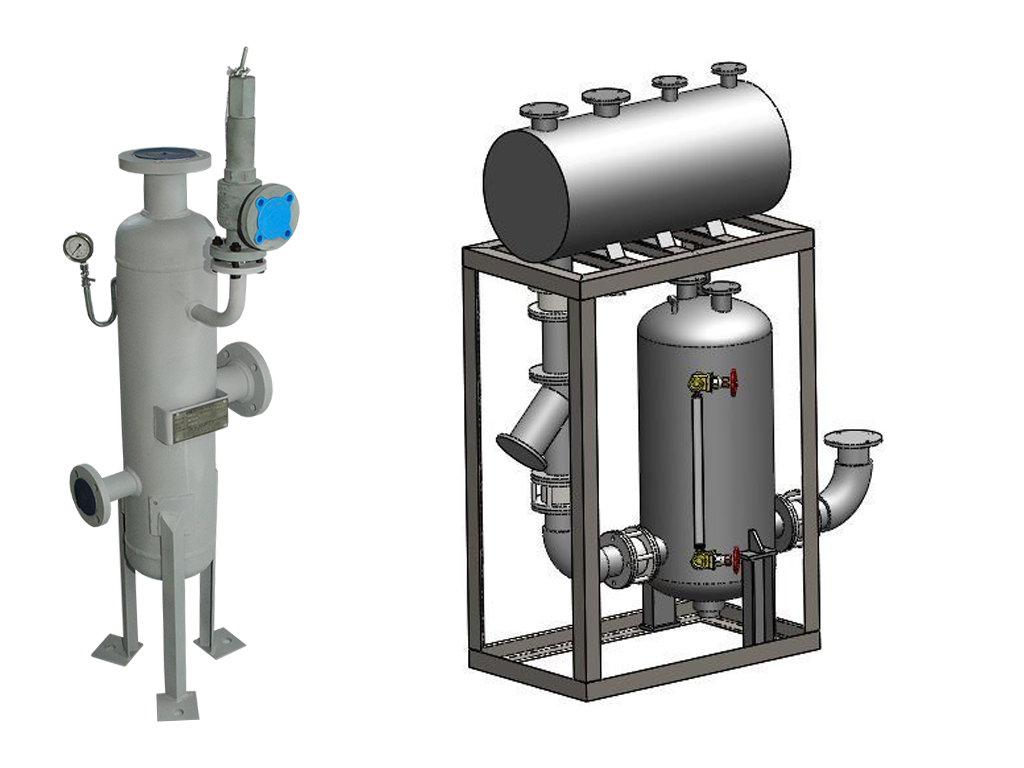

Flash stream recovery vessel

The flash vessel provides a simple and efficient method to make use of flash steam in the condensate recovery system. Inside the flash vessel, the condensate and the emergent flash steam separate from each other. The steam rising to the top can be fed into a steam line for a technical application, and therefore the steam generation is reduced in the boiler. Additional savings are obtained through reduced expenditure on water purification

Water heat recovery boil

Customized design engineered for your specific solution. Pressures from 15-300 psi steam and 30-160 psi hot water Available with dual chamber design or supplemental firing temperatures to 2,400° F

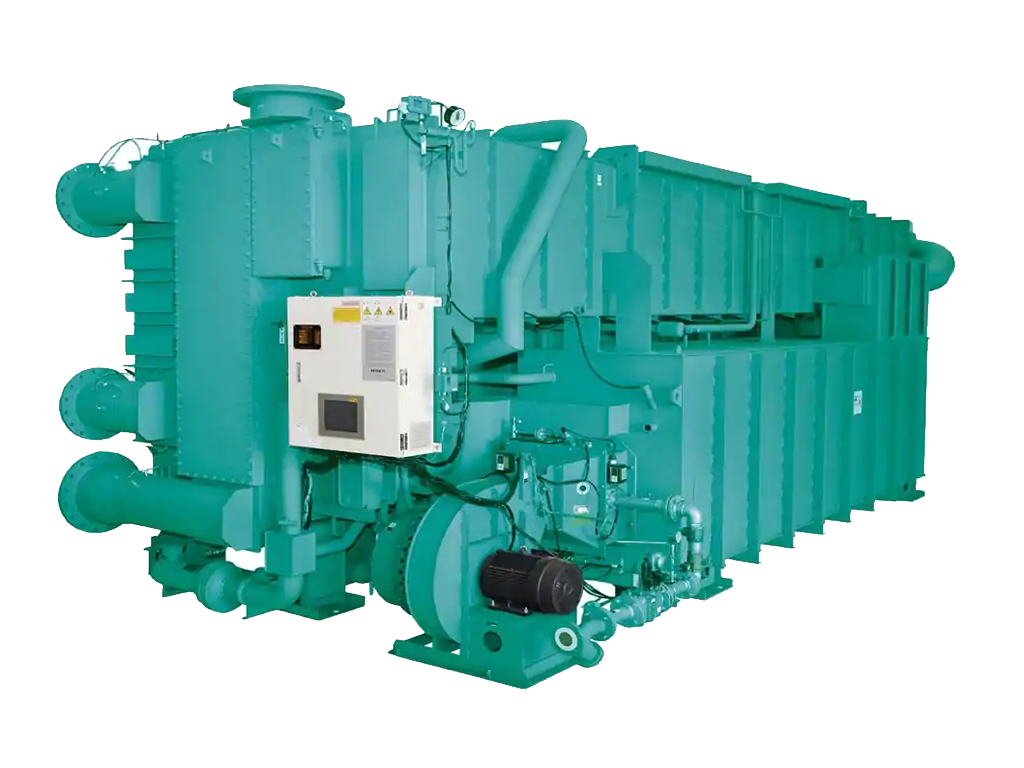

Direct exhaust fire absorption chiller

Customized design engineered for your specific solution. Pressures from 15-300 psi steam and 30-160 psi hot water .Available with dual chamber design or supplemental firing temperatures to 2,400° F

Minimize peak electric demand charges. No CFC or HCFC refrigerants. Using waste heat from radiator heat. So no other fuel required. High reliability and low maintenance.